When navigating the materials landscape, it's crucial to understand the nuances between seemingly similar products such as PET film and polyester film. While the two are related, they are not identical and are suited to different applications. Clarifying these differences is key to selecting the right type of film for your specific needs.

Composition And Structure

PET Film: At its core, Polyethylene Terephthalate (PET) is a durable thermoplastic polymer made from terephthalic acid and ethylene glycol. This material is transformed into PET film through a process called extrusion, where the molten PET resin is formed into a thin, strong film. The process aligns the polymer chains, endowing the film with high strength and stability.

Polyester Film: Broadly speaking, 'polyester film' is an umbrella term that encompasses various polymers, including PET. While PET is the most recognized type of polyester film, there are others like PBT (Polybutylene Terephthalate) and PCT (Polycyclohexylene Dimethylene Terephthalate), each with unique attributes and suited for different applications.

Properties

PET Film: Known for its robustness, PET film features high tensile strength, chemical resistance, and excellent electrical insulation properties. These characteristics make it a versatile material in diverse industries. Its thermal stability across a broad temperature range further broadens its utility.

Polyester Film: While all polyester films, including PET, share core properties such as tensile strength and chemical resistance, variations like PBT and PCT films exhibit tailored properties for specific environments. For example, PBT's enhanced heat resistance is advantageous in the automotive sector.

Applications

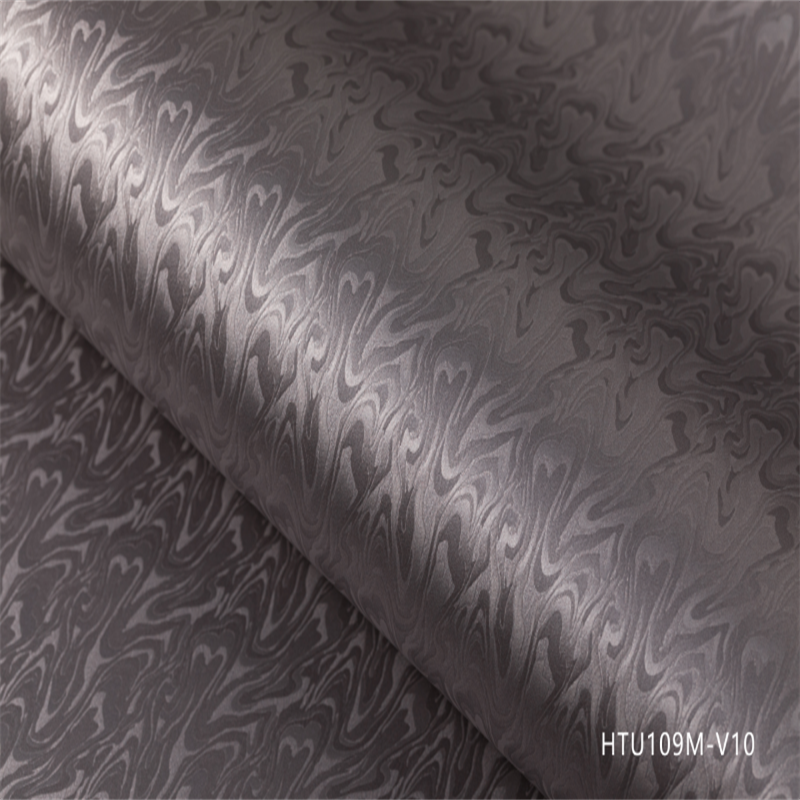

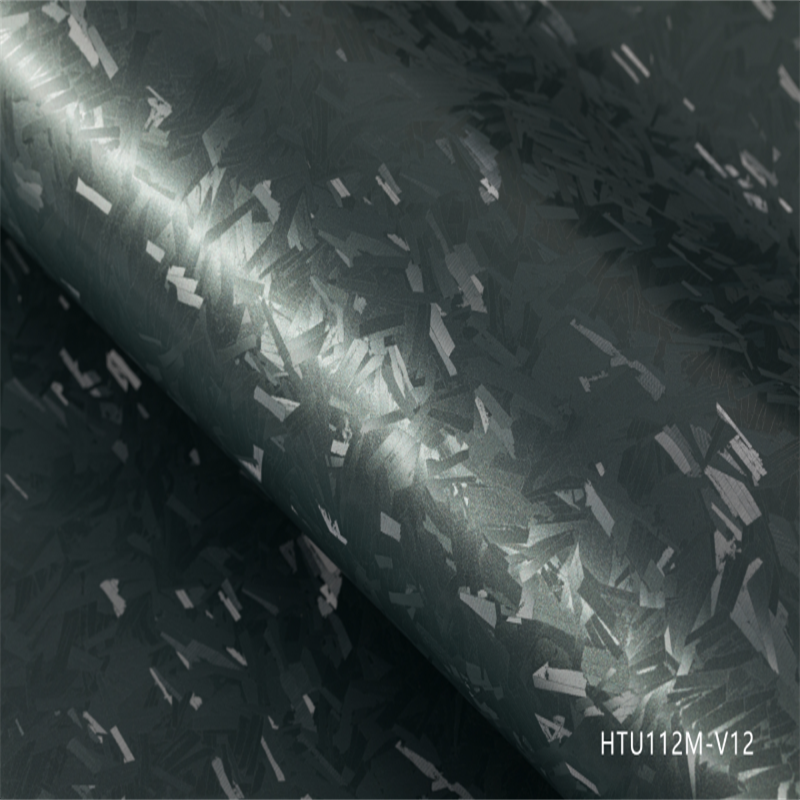

PET Film: The superior qualities of PET film have cemented its role in multiple industries. It's a material of choice for packaging, offering protection and extending product shelf life. Its electrical insulation is invaluable in electronics, while its light transmittance makes it useful in solar energy applications.

Polyester Film: Beyond PET, other polyester films like PBT and PCT are chosen for their specialized properties, finding use in electronics, automotive components, and other high-performance areas.

Clarity And Transparency

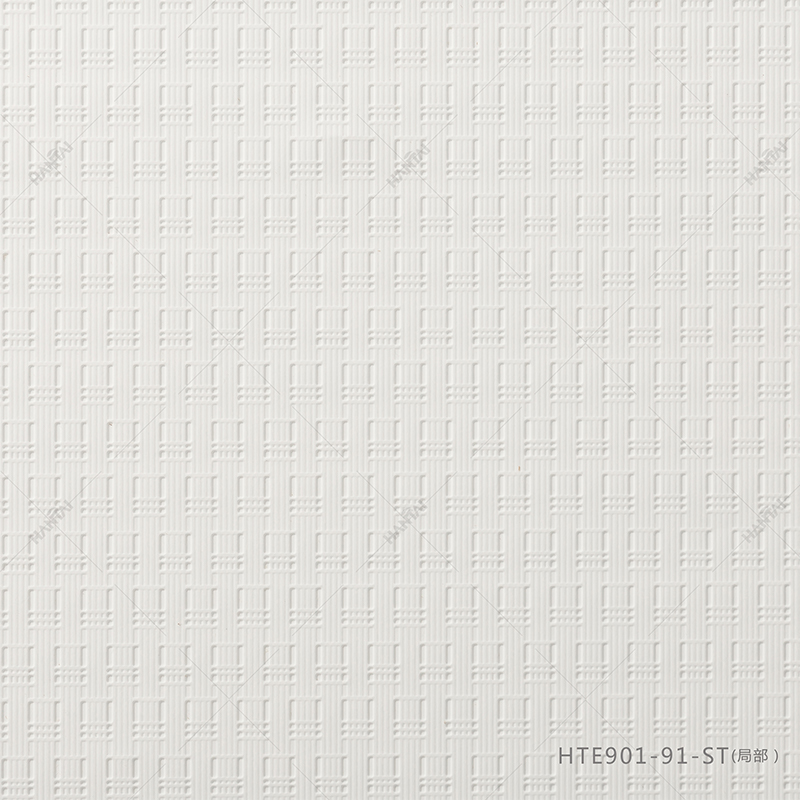

PET Film: The clarity and transparency of PET film are unparalleled, thanks to its amorphous nature and meticulous manufacturing process. This results in a film that, when applied to surfaces, is virtually invisible, maintaining the integrity of the visual design.

Polyester Film: Polyester films generally offer excellent clarity. However, for applications where the highest transparency is crucial, PET film is often the preferred choice due to its superior optical properties.

Conclusion

PET film is a specific type of polyester film, and the terms are often used interchangeably due to the prevalence of PET in the polyester film category. Both materials have great characteristics and have several uses in a variety of sectors. HANTAI is a leading PET film supplier in China, offering various interior decoration films. If you are interested in it, browse our website for more product details!