In the realm of packaging and film materials, Polyethylene Terephthalate (PET) and Polyvinyl Chloride (PVC) films are two of the most widely utilized options. Each material possesses unique properties, applications, and environmental impacts that make them suitable for different purposes. This article delves into the differences between PET and PVC films, examining their physical properties, applications, environmental considerations, and more.

Overview of PET and PVC Films

What is PET Film?

Polyethylene Terephthalate (PET) is a thermoplastic polymer celebrated for its excellent mechanical properties. PET film is known for its clarity, strength, and resistance to moisture and chemicals. It finds common use in food packaging, electronics, and medical applications.

What is PVC Film?

Polyvinyl Chloride (PVC) is another thermoplastic polymer extensively utilized in packaging and construction materials. PVC film is recognized for its flexibility, durability, and affordability. It is often employed in applications such as shrink wrapping, surface covering, and decorative films.

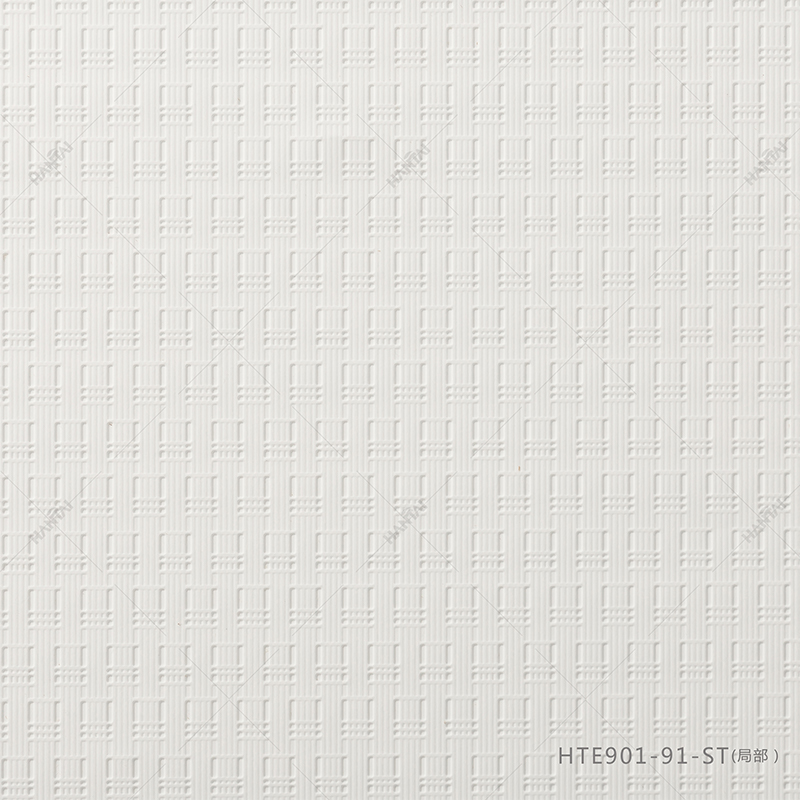

Solid Pvc Film For Living Room Furniture Lamination

Physical Properties Comparison

The physical properties of PET and PVC films significantly influence their applications.

Transparency

PET film typically boasts a transparent, glass-like appearance, making it ideal for showcasing products. In contrast, PVC film can range from transparent to opaque depending on its formulation; however, it generally does not achieve the same level of clarity as PET.

Flammability

PET film is generally flammable but can be treated to enhance flame resistance. PVC film, on the other hand, exhibits flame retardant properties due to the presence of chlorine in its chemical structure.

Flexibility

When it comes to flexibility, PET film is less flexible compared to PVC; it tends to be more rigid. Conversely, PVC film is highly flexible, making it suitable for applications requiring bending or conforming to surfaces.

Scratch Resistance

In terms of scratch resistance, PET film typically performs better than PVC film. This makes PET a preferred choice for applications where surface integrity is crucial.

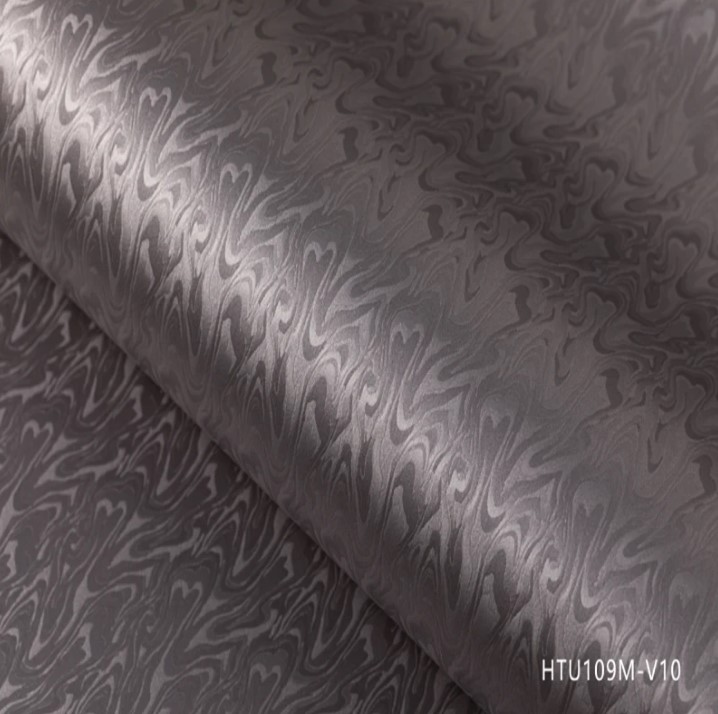

Pvc Wrapping Film Manufacturer

Applications of PET and PVC Films

The distinct physical properties of these films lead to varied applications across different industries.

Applications of PET Film

Food Packaging: Due to its non-toxicity and excellent barrier properties.

Medical Packaging: Utilized for sterile packaging materials.

Electrical Insulation: Commonly used in capacitors and flexible printed circuit boards.

Labels and Tapes: Frequently used in label production because of its clarity and printability.

Applications of PVC Film

Shrink Wrapping: Often employed for food products like meats and cheeses.

Decorative Films: Used in home decor due to its flexibility and printability.

Surface Protection: Serves as a protective layer for various surfaces including panels and furniture.

Industrial Packaging: Suitable for general packaging needs due to its affordability.

Environmental Considerations

Recyclability

PET film is highly recyclable; it can be processed into new products with minimal degradation in quality. The recycling rate for PET is significantly higher than that of PVC. In contrast, recycling PVC film presents challenges due to contamination concerns; it can release harmful chemicals during incineration, posing environmental risks.

Health Concerns

PET film is generally considered safe for food contact; it does not leach harmful substances when heated. In contrast, PVC film contains plasticizers that may leach out under certain conditions, raising health concerns particularly in food packaging.

Economic Factors

Cost Comparison

Typically, PET film is more expensive than PVC due to its superior properties and recyclability. Conversely, PVC film is more cost-effective for short-term applications where durability may be less critical.

Market Trends

The demand for PET film has been growing rapidly due to increasing awareness of environmental issues and the push towards sustainable packaging solutions. Conversely, while PVC remains popular due to its low cost, it faces scrutiny over its environmental impact.

Conclusion

In summary, both PET and PVC films possess unique characteristics that make them suitable for different applications. While PET offers superior clarity, strength, recyclability, and safety for food contact, PVC provides flexibility and cost-effectiveness for various industrial uses. The choice between these materials should be guided by specific application requirements, environmental considerations, and economic factors. As sustainability becomes increasingly important in packaging decisions, PET film is likely to gain further traction over PVC in many sectors.